Kwinkqubo yokusebenzisa iibhokisi, kukho iingxaki ezimbini eziphambili:

1. Ibhegi yamafutha okanye ibhegi eqhumayo2. Ibhokisi eyonakeleyo

Umxholo woku-1

Enye, ibhegi enamafutha okanye igubu isizathu

1. Ukukhetha okungafanelekanga kohlobo lwefluti

2. Impembelelo yokupakisha iifotsholo ezigqityiweyo

3. Ayikhange igqibe ubungakanani bomphakamo webhokisi

Eyesibini, Amanyathelo okusombulula amanqatha okanye iibhokisi eziqhumayo

1. Qinisekisa uhlobo lwamathanki lwebhokisi njengohlobo olufanelekileyo

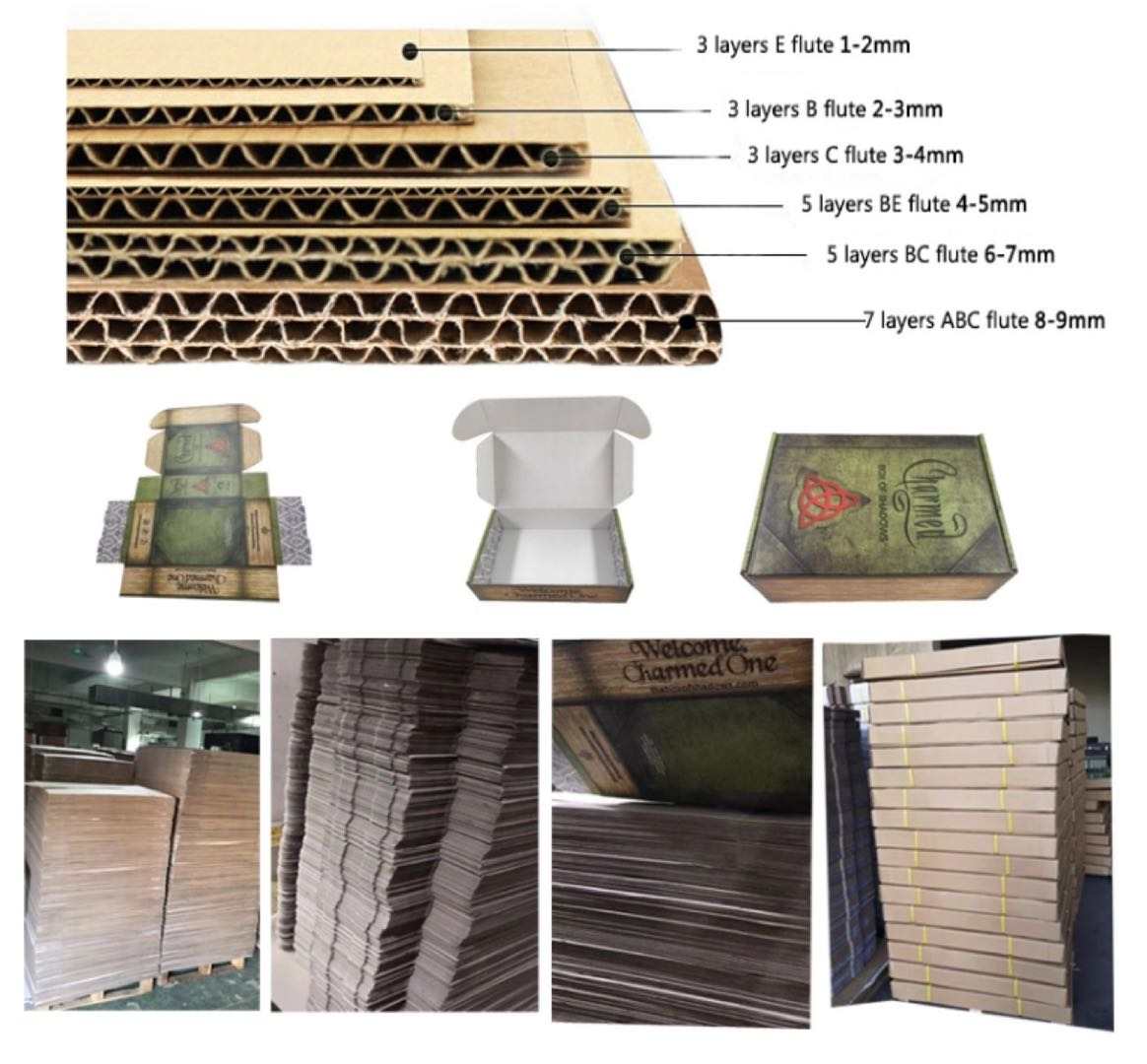

Phakathi kohlobo lwe-A, uhlobo lwe-C, kunye noHlobo lwe-B, udidi lwe-B lunobude obuphantsi be-corrugation, kwaye nangona ukuxhatshazwa koxinzelelo oluthe nkqo kubi, uxinzelelo lwenqwelomoya lolona lungcono. Emva kokuba i-carton ithathe i-B-type corrugation, nangona amandla oxinzelelo lwe-carton engenanto iya kuncipha, iziqulatho ziyazixhasa kwaye zinokuthwala inxalenye yobunzima be-stacking xa zifakwe, ngoko ke umphumo wokupakisha wemveliso ulungile. Kwimveliso yangempela, iintlobo ezahlukeneyo zeflute zinokukhethwa ngokwemiqathango ethile.

2. Ukuphucula iimeko zokupakishwa kweemveliso kwindawo yokugcina impahla

Ukuba indawo yendawo yokugcina impahla iyakuvumela, zama ukungapakishi imihlakulo emibini phezulu. Ukuba kuyimfuneko ukupakisha iifosholo ezimbini phezulu, ukwenzela ukuthintela ukuxinwa komthwalo xa iimveliso ezigqityiweyo zifakwe, i-cardboard edibeneyo inokuthi ifakwe phakathi kwe-stack okanye ifosholo ecaba ingasetyenziswa.

3. Qinisekisa ubungakanani obuchanekileyo beebhokisi

Ukuze kuncitshiswe iingxowa ezityebileyo okanye i-bulges kunye nokubonakalisa isiphumo esihle sokupakisha, sibeka ukuphakama kwebhokisi ukuba kufane nokuphakama kwebhotile, ngokukodwa kwiibhokisi zesiselo se-carbonated kunye neetanki zamanzi ezicocekileyo ezinobude obuphezulu beebhokisi.

Umxholo wesi-2

Enye, eyona nto iphambili yomonakalo webhokisi

1. Ubungakanani boyilo lwekhathoni alunangqiqo

2. Ubukhulu bekhadibhodi ye-corrugated ayihambelani neemfuno

3. Ukuguqulwa kwamazinki kwiibhokisi

4. Uyilo olungenangqiqo lwemigangatho yekhadibhodi yebhokisi

5. Ukomelela kwebhondi yebhokisi kubi

6. Uyilo lokushicilela lwebhokisi alunangqiqo

7. Imigaqo ekwiphepha elisetyenziswe kwibhokisi ayinangqiqo kwaye iphepha elisetyenzisiweyo alihambisani neemfuno

8. Iziphumo zothutho

9. Ukulawulwa kakubi kwendawo yokugcina impahla yomthengisi

Amanyathelo amabini, athile okusombulula umonakalo webhokisi

1. Yila ubungakanani bebhokisi obufanelekileyo

Xa uyila iibhokisi, ukongeza ekucingeni indlela yokusebenzisa ezona zixhobo zinoqoqosho kakhulu phantsi komthamo othile, kufuneka kwakhona uqwalasele izithintelo kubungakanani kunye nobunzima bebhokisi enye kwikhonkco lokujikeleza kweemarike, imikhwa yokuthengisa, imigaqo ye-ergonomic, kunye nokulula kunye nengqiqo yolungiselelo lwangaphakathi lweemveliso. isondo njl. Ngokomgaqo we-ergonomics, ubungakanani obufanelekileyo bebhokisi abuyi kubangela ukukhathala kunye nokulimala kumzimba womntu. Ukupakishwa kweebhokisi ezigqithisileyo kuya kuchaphazela ukusebenza kakuhle kwezothutho kunye nokwandisa amathuba omonakalo. Ngokwendlela yorhwebo lwamazwe ngamazwe, umda wobunzima bebhokisi yi-20kg. Kwintengiso yokwenyani, kwimveliso efanayo, iindlela ezahlukeneyo zokupakisha zinokuthandwa okwahlukileyo kwimarike. Ke ngoko, xa uyila ikhathoni, zama ukumisela ubungakanani bepakethi ngokwemikhwa yokuthengisa.

Ke ngoko, kwinkqubo yoyilo lweekhathoni, izinto ezahlukeneyo kufuneka ziqwalaselwe ngokupheleleyo, kwaye amandla oxinzelelo lwebhokisi kufuneka aphuculwe ngaphandle kokunyusa iindleko kunye nokuchaphazela isiphumo sokupakisha. Kwaye emva kokuqonda ngokupheleleyo iimpawu zemixholo, misela ubungakanani obufanelekileyo bebhokisi.

2. Ikhadibhodi ekhutshiweyo ifikelela kubukhulu obuchaziweyo

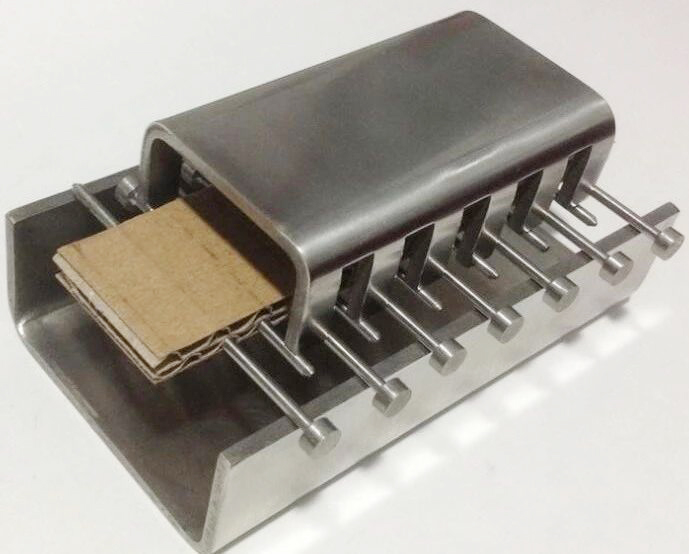

Ubunzima bekhadibhodi eboshiweyo bunempembelelo enkulu kumandla oxinzelelo lwebhokisi. Ngethuba lenkqubo yokuvelisa, i-roller corrugating igugile kakhulu, okubangela ukuhla kobunzima bekhadibhodi ye-corrugated, kunye nokunciphisa amandla okuxinzelela kwebhokisi, okubangelwa ukunyuka kwesantya sokuphuka kwebhokisi.

3. Nciphisa i-deformation of corrugated

Okokuqala, kuyimfuneko ukulawula umgangatho wephepha lesiseko, ngakumbi izikhombisi ezibonakalayo ezifana namandla okutyumza umsesane kunye nokufuma kwephepha eliphakathi. Okwesibini, inkqubo yekhadibhodi ye-corrugated ifundelwa ukuguqula i-deformation corrugated ebangelwa yizinto ezifana nokunxiba kwee-roller corrugated rollers kunye noxinzelelo olunganeleyo phakathi kwee-roller corrugated rollers. Okwesithathu, ukuphucula inkqubo yokuvelisa i-carton, ukulungelelanisa i-gap phakathi kwee-roller feed paper of the machine carton, kwaye utshintshe i-carton yoshicilelo kwi-flexographic yokushicilela ukunciphisa i-corrugated deformation. Kwangaxeshanye, kufuneka sinikele ingqalelo ekuthuthweni kweekhathoni, kwaye sizame ukusebenzisa iiveni ukuthutha iibhokisi ukunciphisa ukonakala okubangelwa kukudityaniswa kwelaphu leoli kunye neentambo kunye nokunyathelwa kwee-stevedores.

4. Yila inani elifanelekileyo leeleya zekhadibhodi enamalahle

Ikhadibhodi ekhutshiweyo inokohlulwa ibe ngumaleko omnye, imigangatho emithathu, imigangatho emihlanu kunye nesixhenxe ngokwenani leeleya zezinto. Njengoko inani leeleya lisanda, linamandla aphezulu oxinzelelo kunye namandla okupakisha. Ke ngoko, inokukhethwa ngokweempawu zemveliso, iiparamitha zokusingqongileyo kunye neemfuno zabathengi.

5. Yomeleza ulawulo lwamandla e-peel yeebhokisi ze-corrugated

Amandla okudibanisa phakathi kwephepha le-corrugated core ye-carton kunye nephepha lobuso okanye iphepha langaphakathi lingalawulwa ngezixhobo zokuvavanya. Ukuba amandla e-peel akahambelani neemfuno eziqhelekileyo, fumana isizathu. Ababoneleli kufuneka bomeleze ukuhlolwa kwezinto eziluhlaza zebhokisi, kwaye ukuxinwa kunye nomxholo wephepha kufuneka uhlangabezane nemigangatho yelizwe efanelekileyo. Kwaye ngokuphucula umgangatho we-adhesive, ukuphucula izixhobo, njl.njl ukufezekisa amandla e-peel afunwa ngumgangatho wesizwe.

6. Uyilo olunengqiqo lwepateni yebhokisi

Iikhathoni kufuneka zizame ukunqanda ukushicilelwa kwephepha elipheleleyo kunye noshicilelo oluthe tye, ngakumbi ushicilelo oluthe tye kumbindi webhokisi, kuba umsebenzi walo uyafana nowomgca woxinzelelo othe tye, kwaye uxinzelelo lokushicilela luya kutyumza i-corrugated. Xa uprinta uyilo kwibhokisi yebhokisi yebhokisi, kuyimfuneko ukunciphisa inani lerejista yombala. Ngokuqhelekileyo, emva kokushicilelwa kombala omnye, amandla oxinzelelo lwebhokisi ancitshiswa nge-6% -12%, ngelixa emva kokuprintwa kwemibala emithathu, iya kuncitshiswa nge-17% -20%.

7. Ukumisela imimiselo yephepha elifanelekileyo

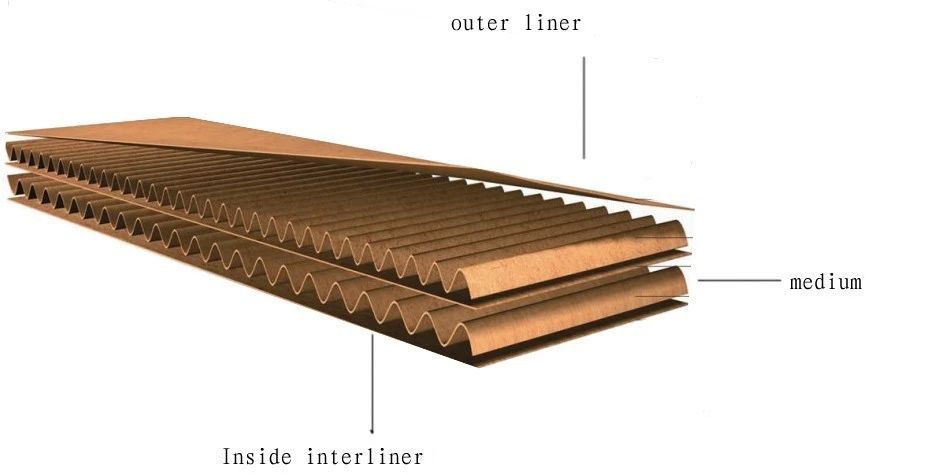

Kwinkqubo ethile yoyilo lwephepha lebhokisi, iphepha elisisiseko elifanelekileyo kufuneka likhethwe ngokufanelekileyo. Umgangatho wemathiriyeli ekrwada yeyona nto iphambili emisela amandla oxinzelelo lweekhathoni zamathanki. Ngokuqhelekileyo, amandla anyanzeliswayo eebhokisi ze-corrugated ahambelana ngokuthe ngqo nobuninzi, ukuqina, ukuqina, ukuqina komsesane onqamlezayo kunye nezinye izibonakaliso zephepha lesiseko; ihambelana ngokuphambeneyo nomxholo wokufuma. Ukongezelela, impembelelo yomgangatho wokubonakala kwephepha lesiseko kwi-compressive force of the carton ayikwazi ukuhoywa.

Ke ngoko, ukuze kuqinisekiswe amandla aneleyo oxinzelelo, okokuqala, kufuneka kukhethwe izixhobo ezikumgangatho ophezulu. Nangona kunjalo, xa uyila iphepha elisetyenziselwa iibhokisi, musa ukwandisa ubunzima kunye nebakala lephepha kwaye unyuse ubunzima obupheleleyo bekhadibhodi. Enyanisweni, amandla oxinzelelo lweebhokisi ze-corrugated kuxhomekeke kwimpembelelo edibeneyo ye-ring compressive yamandla ephepha lobuso kunye nephepha eliphakathi. I-corrugated medium inempembelelo enkulu kumandla, ngoko ke kungakhathaliseki ukuba amandla okanye ukuqwalaselwa kwezoqoqosho, umphumo wokuphucula ukusebenza kwebakala eliphakathi kwe-corrugated kungcono kunokuphucula umgangatho wephepha lomhlaba, kwaye uqoqosho kakhulu. Kunokwenzeka ukulawula iphepha elisetyenziswe kwiibhokisi ngokuya kumthengisi ukuze uhlolwe kwindawo, ukuthatha iisampulu zephepha lesiseko, kunye nokulinganisa uluhlu lwezalathisi zephepha lesiseko ukukhusela iikona zokusika kunye ne-shoddy.

8. Ukuhanjiswa okuphuculweyo

Ukunciphisa ukuphindaphinda kwezinto zokuthutha kunye nokuphatha, ukwamkela indlela yokuhanjiswa okukufutshane, kunye nokuphucula indlela yokuphatha (kucetyiswa ukuba usebenzise ifosholo yokuphatha); ukufundisa abathwali, njl.njl., baphucule ulwazi lwabo lomgangatho, kwaye bathintele ukulayisha kunye nokothula; nikela ingqalelo kwimvula kunye nomswakama xa ulayisha kunye nokuthutha , ukubopha akukwazi ukuqina kakhulu, njl.

9. Ukuqinisa ulawulo lweendawo zokugcina abathengisi

Umgaqo-siseko wokuqala wokuqala kufuneka ulandelwe kwiimveliso ezithengiswayo, inani leeleyile ezipakishweyo akufanele libe phezulu kakhulu, indawo yokugcina impahla akufanele ifume kakhulu, kwaye kufuneka igcinwe yomile kwaye ifakwe umoya.

Ixesha lokuposa: Feb-07-2023